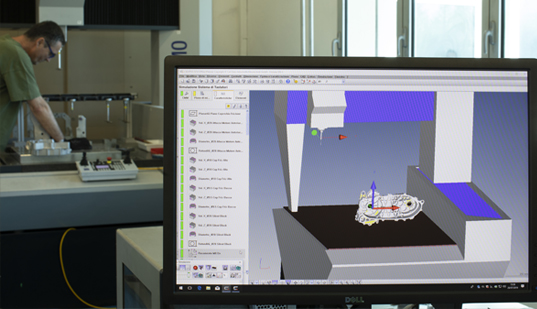

ENGINEERING

Our engineering staff designs production processes and jigs in Assembly, Machining and Logistic areas, based on their own proven experiences and lean manufacturing rules.

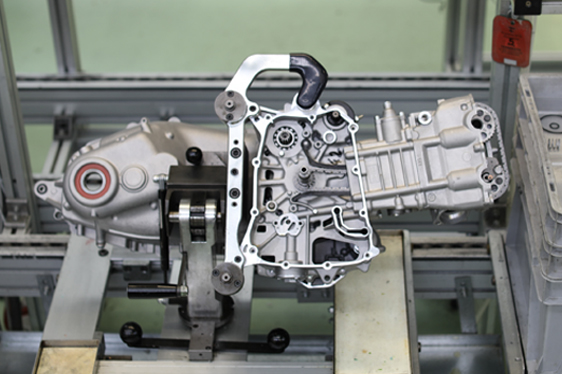

ASSEMBLY

The engines are assembled on flexible assembly lines equipped with manual and automated workstations with a high technological content and equipped with integrated process control systems that guarantee the absolute quality, efficiency and traceability of all operations.

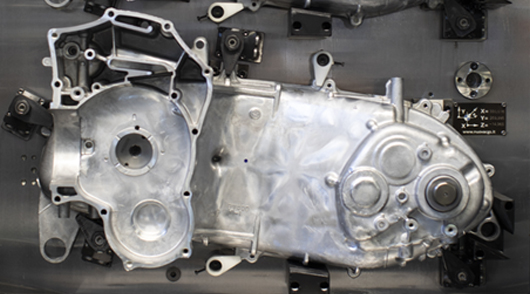

MACHINING

Machining division includes Aluminum Division and Steel one.

The machining processes are carried out by highly technological work centers, equipped with a process control system for monitoring all the parameters necessary to guarantee the quality of the process and the products.

LOGISTICS

- Stream optimization

- Synchronization vs processes

- Traceability of individual parts

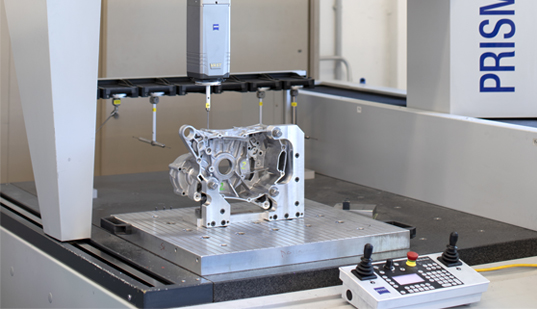

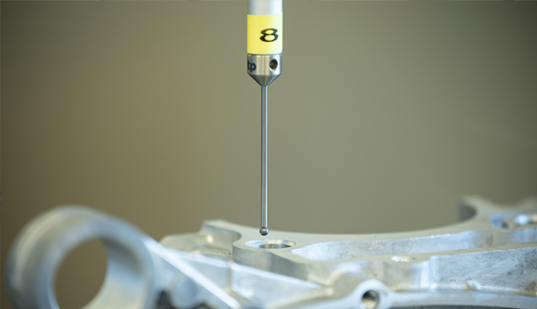

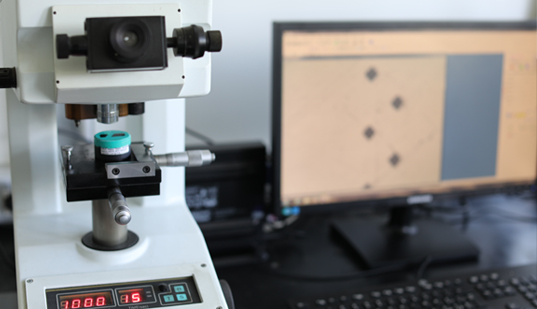

QUALITY ASSURANCE

In Motori Minarelli Quality Department there are 3D control tools, profile detectors, profile gauge, heat treatment instrument for steel parts, spectrum material structure detector.

Highly skilled staff includes people who daily monitor all internal processes and incoming materials.

This high specialization, combined with the latest generation instruments, allows us to obtain very high quality products for the whole European market.